Motivation and objectives

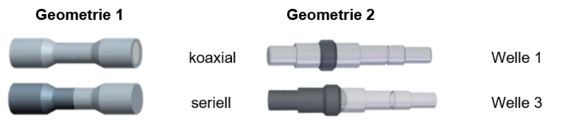

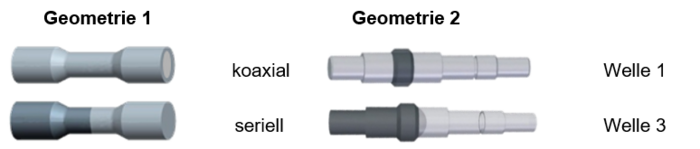

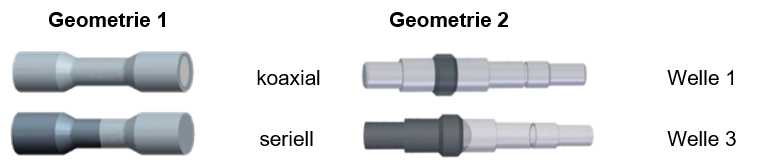

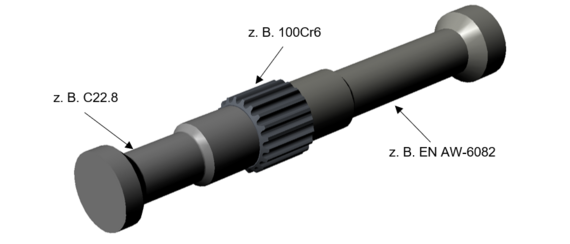

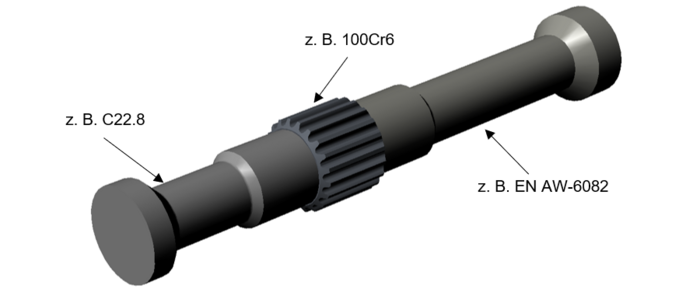

In general, CRC 1153 investigates two different material arrangements: coaxial and serial (Fig. 1). These arrangement principles can be transferred to real components: In order to reduce the component weight, it is possible to produce segments of a previously monolithic component from a light metal - this results in a serial hybrid component with lower component mass (compare Fig. 1 and Fig. 4, shaft 3). To increase the wear resistance, a segment (e.g. a bearing seat) of a component can be coated with a hard material (compare Fig. 1 and Fig. 3, shaft 1).

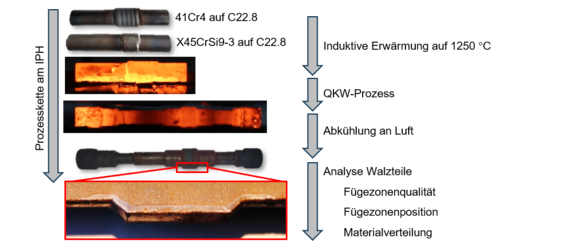

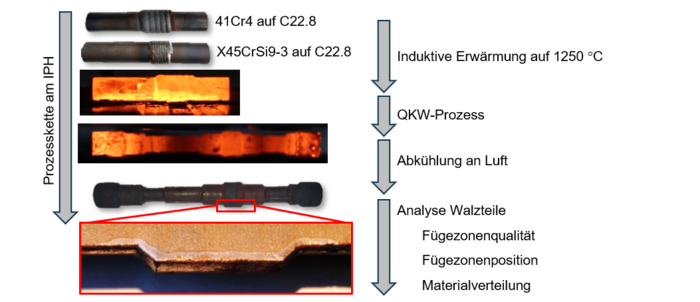

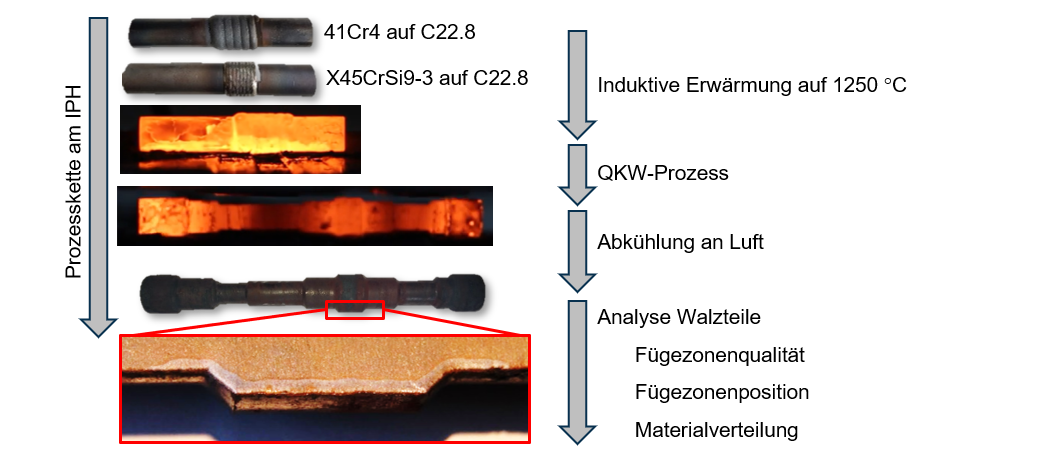

One challenge is the heating of the semi-finished products/billets, which is necessary for forming, since the hybrid semi-finished product has different flow resistances due to the different materials and may have to be heated inhomogeneously in order to enable uniform forming. An inductive heating system at IPH is used for this purpose (Fig. 2).

The rolling processes are designed by means of FEM simulation and investigated experimentally. The results of the rolling process will be evaluated, and a design method developed. Moreover, the processes will be improved with regard to stability and quality. The aim is to produce hybrid components for hybrid semi-finished products from various combinations of various materials (including 20MnCr5, 41Cr4, C22.8, EN AW-6082, X45CrSi9-3, 100Cr6, Stellite-6, Delcrome 253, Inconell 625 and X5CrNi18-10) both simulative and experimentally using cross-wedge rolling.

Results

The main research areas of the first funding period (FP) were the creation of a first simulation model for the calculation of the cross-wedge rolling of hybrid semi-finished products (multi-material simulation) and the design of cross-wedge rolling tools in order to be able to roll the geometry of the demonstrator "shaft". Subsequently, the quality of the joining zone and the influence of the joining process on the shape and stability of the joining zone as well as on the quality of the forming process (tolerance, process error, quality) were investigated both simulative and experimentally. In addition, the influence of the different flow resistances of the materials and the associated suitable component temperature for controlled forming were examined. It turned out that the best forming result is achieved with inhomogeneous component heating of hybrid aluminium-steel semi-finished products. The geometry and position of the joining zone can be influenced by the forming parameters. Particularly high degrees of deformation in the area of the coaxial coating material produce a uniform, fine-grained microstructure. Thus, the fundamental applicability of tailored forming to the transverse wedge process was determined during the first conveying period.

Current work and outlook

In addition, a process monitoring system is being developed within the framework of the subproject which makes it possible to measure process variables such as temperature and force in the contact between semi-finished product and tool during cross-wedge rolling. An intelligent database will be used to perform an automated process variable correction at a later stage and thus a rolling parameter control to stabilize the cross-wedge rolling process for a large number of material and geometry combinations. In particular, the integration of functions is increased by rolling in gearing consisting of an alloy other than the shaft material.

The results of this subproject should enable the design of cross-wedge rolling processes for hybrid components. The determination of the formability of the hybrid semi-finished products produced by other subprojects is also one of the objectives.

Publications

Subproject leader

30419 Hannover

Staff

30419 Hannover