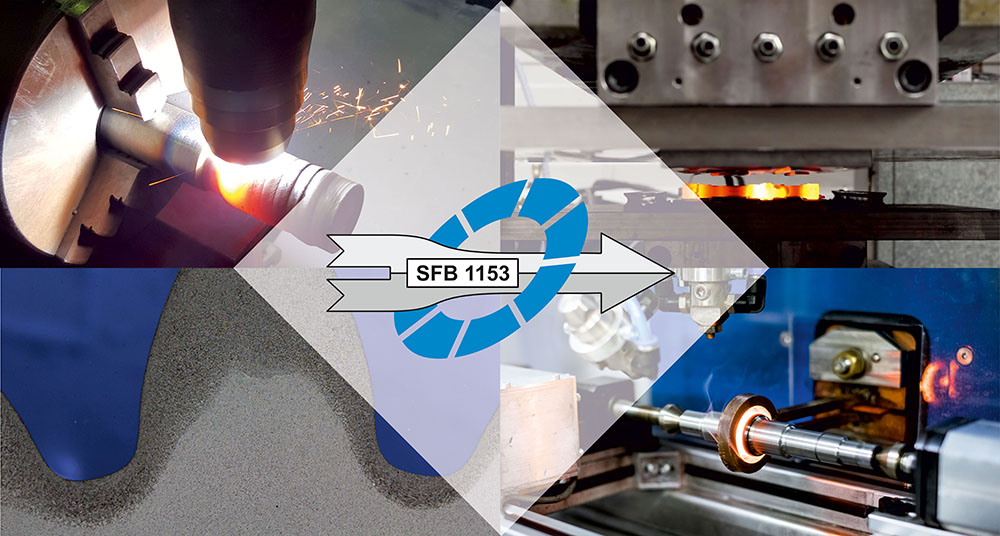

In recent years, the requirements for technical components have steadily been increasing. This development is intensified by the desire for products with lower weight, smaller size and extended functionality, but also higher resistance against specific stresses. Mono-material components, however, which are produced by established processes feature limited qualities according to their respective material characteristics. Thus, a significant increase in production quality and efficiency can only be reached by combining different materials in one component.

Objectives

The superior aim of the Collaborative Research Centre 1153 “Tailored Forming“ is to develop potentials for hybrid solid components on the basis of a new process chain by using joined semi-finished workpieces. In contrast to existing process chains of hybrid solid components, at which the joining process takes place during forming or at the end of the process chain, tailored semi-finished workpieces are used in the CRC, which are joined before the forming process. Thus, it will be possible in the future to produce complex highly stressable solid components made of different metals, which can not be produced yet according to the current state of technology.

Scientific Questions

- Which material combinations and joining processes are suitable for the new technology?

- Which mechanical and physical material properties can be achieved by forming or producing residual stresses within the structure and in which way does it affect the joining zone?

- Which forming limits and geometrics are possible depending on the chosen material combination and which degrees of deformation can be reached by the forming process?

- How can the forming process be modeled and in which way are predictions and conclusions in this context possible to adequately describe the production process?

- Which design principles must be observed and which methods of process monitoring and quality control are suitable for such components?